许多半导体厂迈向智慧化的过程中,开始发现环境中存在肉眼看不到的微污染物,它们悬浮在空气中,对产品造成莫大伤害,但传统HEPA或ULPA等过滤方式却难以有效去除;因而亟思在厂区内布建智慧化管控机制,以解决AMC(Airborne Molecular Contamination)问题。

普拉爱尔技术专家熊伟表示,随着半导体先进制程的发展,透过传统过滤方式,已能有效控制空气中悬浮的粉尘;但相较于粉尘,其他有机或无机的微污染物,对制程良率则有更巨大的影响。换言之高效能AMC微污染控制技术,是目前半导体大厂发展5奈米先进制程的关键要素之一。

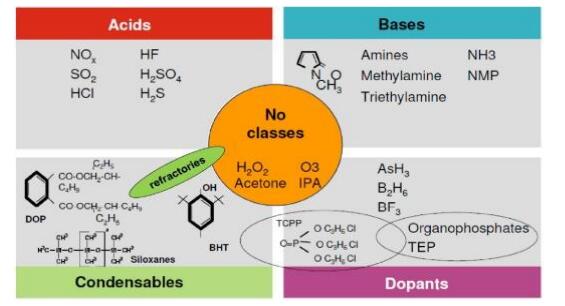

AMC主要分为MA酸性物质、MB咸性物质、MC凝结性物质及MD掺加物质,及H₂O₂、O₃等无法归类者,这些气态分子污染物,以尺寸来看仅需要5~25个分子沉积,便可占满5奈米线宽,导致该晶片损坏,这是目前半导体业者面临大的难题。

为解决此问题,化学滤网从业者在传统粉尘滤网外叠加多效化学滤网,亦即传统三合一化学滤网模组模。但它延伸出莫大问题,即业者为确保效能达到高水准,因而采用大量PU胶将滤网封在金属框内,一来PU胶本身就释出污染源,二来碍于金属与滤材被黏死而无法更换,最终只会沦为复合型态的废弃物。

锐智研发的环保组合式滤网,则呈现截然不同风貌。我司将归纳它拥有诸多优势,首先完全不使用PU胶、让用户因而节省3%~5%成本。其次将框体设计为独特的抽取式或堆叠式,方便用户仅需替换单层滤材,不需要取下整组滤网,相对轻量且安全性佳。第三,模组化外框可重复使用,更换简易,与传统三合一化学滤网形成极大反差。第四,因滤材与外框可重复使用,使购置成本减少40%以上、废弃物减量60%以上,连带降低废弃物堆积与后续处理费用。第五,环保型滤网让备品仅剩滤材,外框可多次使用到耗损才需补充。

锐智以3R--Reduce(减少)、Reuse(重复利用)、Recycle(回收利用)为核心理念,期望达到零废弃物目标,世界正面临气候变迁、全球暖化、频繁出现极端气候等严峻的环境议题,所以人类不应以「再利用经济」(仍会产生废弃物)为满足,需要更进一步达到「循环经济」,务求100%利用原料资源、不再生成任何废弃物,这正是滤能想要带给产业的全新思维。

除致力发展模组化滤网外,锐智也积极推广另一产品「一体式AMC化学过滤器」,将除酸性、碱性、TVOC等吸附和分解材料负载在一种夹碳布材料里面,做成一体化AMC化学过滤器,该产品可以同时高效去除将除酸性、碱性、TVOC、臭氧等AMC气态污染物,同时产品的性价比较也是比较好,对环境更环保节能。

Eco-friendly combined filter semiconductor factory efficient control AMC and reduce the impact of carbon emissions

Many semiconductor factories are moving towards the process of intellectualization and are beginning to discover that there are micro-pollutants in the environment that are invisible to the naked eye, which are suspended in the air and cause great harm to products, but traditional filtration methods such as HEPA or ULPA are difficult to effectively remove. Contamination) problem.

According to Mr. Yu, the technical director of Filtration Energy, with the development of advanced semiconductor processes, the dust suspended in the air can be effectively controlled through traditional filtration methods; however, compared to dust, other organic or inorganic micro-pollutants have a greater impact on process yields. In other words, high performance AMC micro-pollution control technology is one of the key elements for semiconductor makers to develop 5nm advanced process.

AMC is mainly divided into MA acidic substances, MB salty substances, MC condensation substances and MD doping substances, and H2O2, O3 and other unclassifiable, these gaseous molecular pollutants, in terms of size, only 5 to 25 molecules deposited, can occupy the full 5 nm line width, resulting in damage to the wafer, which is currently the biggest problem faced by the semiconductor industry.

In order to solve this problem, the chemical filter industry in the traditional dust filter outside the superimposed multi-effect chemical filter, that is, the traditional three-in-one chemical filter module module. But it extends to a big problem, that is, the industry in order to ensure the high level of efficiency, so the use of a large number of PU glue to seal the filter in the metal frame, the PU glue itself will release the source of pollution, the second is due to the metal and the filter material is stuck and can not be replaced, and ultimately will only be reduced to a composite waste.

The environmental protection combined filter developed by Filter Energy presents a very different style. First of all, it does not use PU glue at all, so that users can save 3%~5% cost. Secondly, the frame is designed as a unique extraction type or stacking type, so that users only need to replace a single layer of filter material, not to remove the whole set of filters, which is relatively light and safe. Thirdly, the modular frame is reusable and easy to replace, which is a great contrast to the traditional 3-in-1 chemical filters. Fourth, the reusability of filter media and frames reduces the purchase cost by more than 40% and waste by more than 60%, which in turn reduces waste accumulation and subsequent disposal costs. Fifthly, the environmental protection filter allows only the filter media to be used as spare parts, and the outer frame can be used many times until it is worn out before replenishment.

"The world is facing severe environmental issues such as climate change, global warming, and frequent extreme weather, so mankind should not be satisfied with the "reuse economy" (which still generates waste), but needs to go further to achieve a "recycling economy", aiming to We need to go further to achieve a "circular economy" and strive to utilize 100% of raw material resources without generating any waste.

In addition to the development of modular filters, Filtration is also actively promoting another product, "Fluorochemical Coolant Leak Detection and Solution", to help foundries identify the source of contaminants more effectively. This is because foundries have to use Chiller in many machines, but the leakage during its use causes emerging sources of AMC contamination, and Filter Energy's solution is able to test the leakage point within one minute by using a manual probe to block AMC generation from the source.

7X24小时电话 周一至周六 9:00-18:00

0769-23060359

电话:0769-23060359 手机:18818539148(同微信号)丨电话:137-2862-9511

邮箱:jia791221@163.com

地址:广东省东莞市莞龙路东城段162号松源创新科技城C栋

技术支持:赢网科技

备案号:粤ICP备20028820号